Retrofitting older frac pumps with modern controls and added sensors can bring new life to assets that have been working in the field for years. A thoughtful upgrade program can cut downtime, trim fuel use, and give crews clearer data to act on when things go sideways.

Owners who take a systematic approach often find that modest investment yields longer service life and fewer surprise repairs. With a mix of mechanical fixes and smarter electronics it is possible to make older machines behave more like new ones.

Assessing Pump Condition And Retrofit Goals

Begin by taking a hard look at the pump and its support systems to map out what needs repair and what could be upgraded for better performance. Run a baseline test that logs vibration trends, pressure swings, fluid temperatures, and engine operating points so that later improvements can be measured against a clear yardstick.

Talk with operators and maintenance staff to learn where the unit trips most often and what workarounds are in place, since crew knowledge often points to the soft spots.

If you’re considering extending the service life of a frac pump, starting with a detailed condition assessment ensures that every upgrade dollar delivers measurable gains. Set realistic goals that match budget and schedule while keeping an eye on return on uptime and fuel savings.

Upgrading Control Systems With Programmable Logic Controllers

Swapping legacy relay logic or aging analog modules for a modern programmable logic controller brings more than automation, it adds predictability in how the pump responds to changing loads. A PLC can host control loops for speed, suction balance, and pressure sequencing while making it simple to adjust settings from a local panel or a tablet.

When combined with a user friendly human machine interface the crew can see trends, acknowledge alarms faster, and get back to pumping with less guesswork. Pick controllers that are rugged for field use and that support common industrial protocols for future expansion.

Adding Variable Speed Drive And Engine Management

Fitting a variable speed drive to control pump speed can reduce fuel burn and smooth torque demands on the prime mover, which often cuts stress on driveline components. Engine control integration that coordinates fuel rate with pump speed and pressure lessens sudden surges and can reduce thermal cycles that wear seals and bearings.

Make sure the motor, coupling, and drive are rated to handle the full torque envelope and that thermal monitoring is in place so that a quiet problem does not become a loud failure. With a tuned drive and matched engine strategy the unit will often run cleaner and last longer.

Sensor And Telemetry Integration For Condition Monitoring

Install a layered sensor suite that includes pressure transducers, accelerometers, strain monitoring, and temperature probes to create a picture of machine health over time. When those signals feed into simple analytics the team can spot rising vibration trends, seal leaks forming, or a slow loss of flow before a failure shows up in production numbers.

Telemetry that streams selected metrics to a secure server lets off site engineers run root cause checks without hopping on a truck and can speed up diagnosis when the clock is ticking. Make data actionable by filtering raw feeds into alarms that match how crews work so they get useful prompts and not noise.

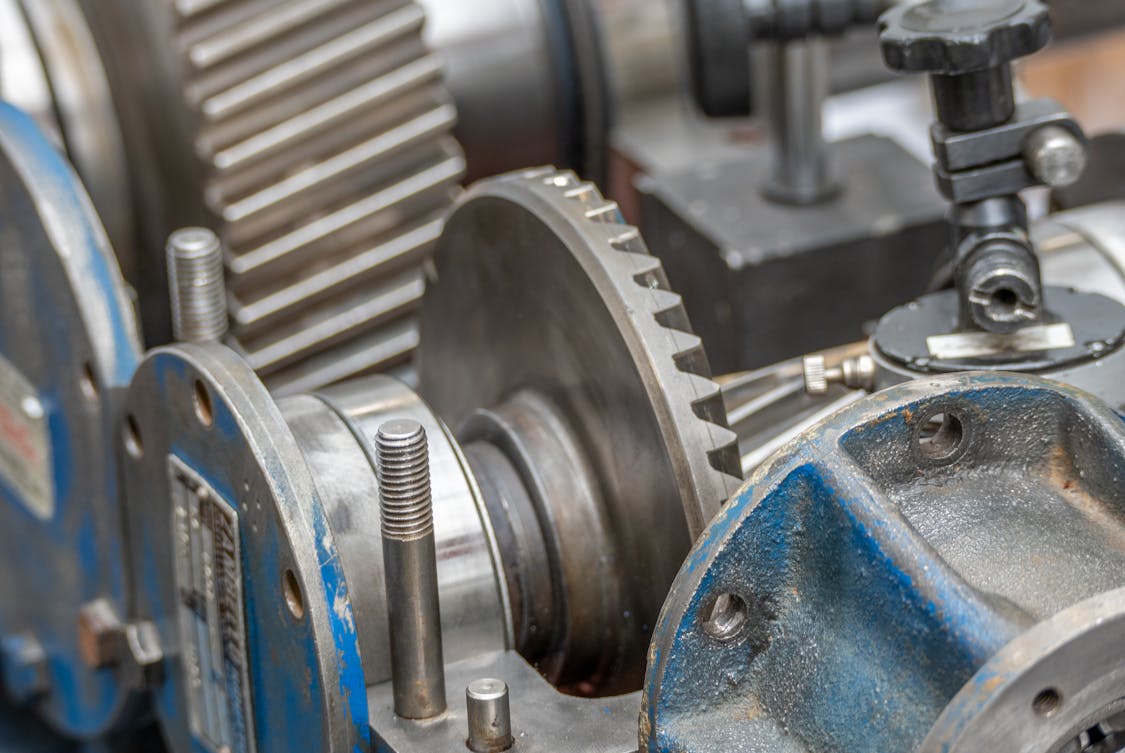

Mechanical Upgrades For Wear Items And Reliability

Replace worn bearings, seals, and couplings with parts that match or improve on original specifications and think about hard facing critical wear surfaces if abrasive fluids are present. Rebalance rotating assemblies and check shaft alignments at final assembly because small misalignments will come back to bite you in the form of vibration and shortened life.

Consider improved filtration and cooling packages that reduce contamination and heat soak which are two of the main enemies of pump longevity. Small mechanical fixes up front can save a lot of time and expense on the back end.

Emissions Control And Flow Management

Upgrading exhaust after treatment and adding flow control hardware can reduce visible emissions and help meet stricter site requirements that may come up over the life of the asset. Flow smoothing devices and better pulsation dampening reduce pressure spikes that stress valves and piping and make the control system’s job easier.

If a new control strategy is planned check how the added components affect backpressure and match materials so corrosion is not introduced at the joints. Managing emissions and flow behavior goes hand in hand with improving reliability.

Safety Systems And Regulatory Compliance

Bring safety systems up to date by integrating automatic shutdown logic for unsafe speed, high vibration, and excessive temperature along with clear visual and audible alerts for on site crews. Review local and regional regulations to confirm that upgrades do not create gaps in permits or reporting obligations and keep documentation handy for inspections.

Training sessions that walk crews through emergency stop sequences and alarm priorities make that extra layer of protection useful when time matters. Better safe than sorry is an old saying, and it applies to machines as much as it does to people.

Training Maintenance Staff And Setting Support Pathways

A retrofit is only as good as the people who run and maintain the upgraded pump, so invest time in hands on training that pairs classroom material with real world drills on the machine. Create a simple fault tree and maintenance checklist that the crew can use on shifts to spot early signs and to decide when to call for extra help.

Establish a clear support pathway with vendors so that spare parts, technical help, and software updates arrive fast when needed. With trained staff and a plan in place the upgraded asset will repay its keep through fewer emergency calls and better uptime.